Established in 1974, ASAS AlMohileb stands as a cornerstone in Saudi Arabia’s construction industry, renowned for its robust Ready-Mix Concrete division. This sector, one of the company’s pioneering ventures, has been instrumental in delivering top-tier concrete solutions across the Kingdom.

Our workforce comprises of highly qualified professionals adept in mix design, ensuring tailored solutions that meet the unique requirements of clients and specialized projects. Holding esteemed certifications, including ISO standards, we exemplify our unwavering commitment to quality management and adherence to international benchmarks. We are pioneers in introducing Self-Compacting Concrete and Green Concrete, reflecting our dedication to sustainable and efficient building methodologies. Our extensive fleet of transit mixers, mobile pumps, and cement bulkers enables us to deliver any quantity of concrete promptly, ensuring seamless supply to projects of all scales. Equipped with fully computerized batching plants and on-site workshops, we maintain stringent quality control and operational efficiency throughout our production processes. At ASAS Al-Mohileb, we continually strive for innovation and optimization, ensuring that our Ready-Mix Concrete division not only meets but exceeds the evolving demands of the construction industry.

At ASAS Al-Mohileb, we continually strive for innovation and optimization, ensuring that our Ready-Mix Concrete division not only meets but exceeds the evolving demands of the construction industry.

THE LINE READY

MIX CONCRETE COMPLEX:

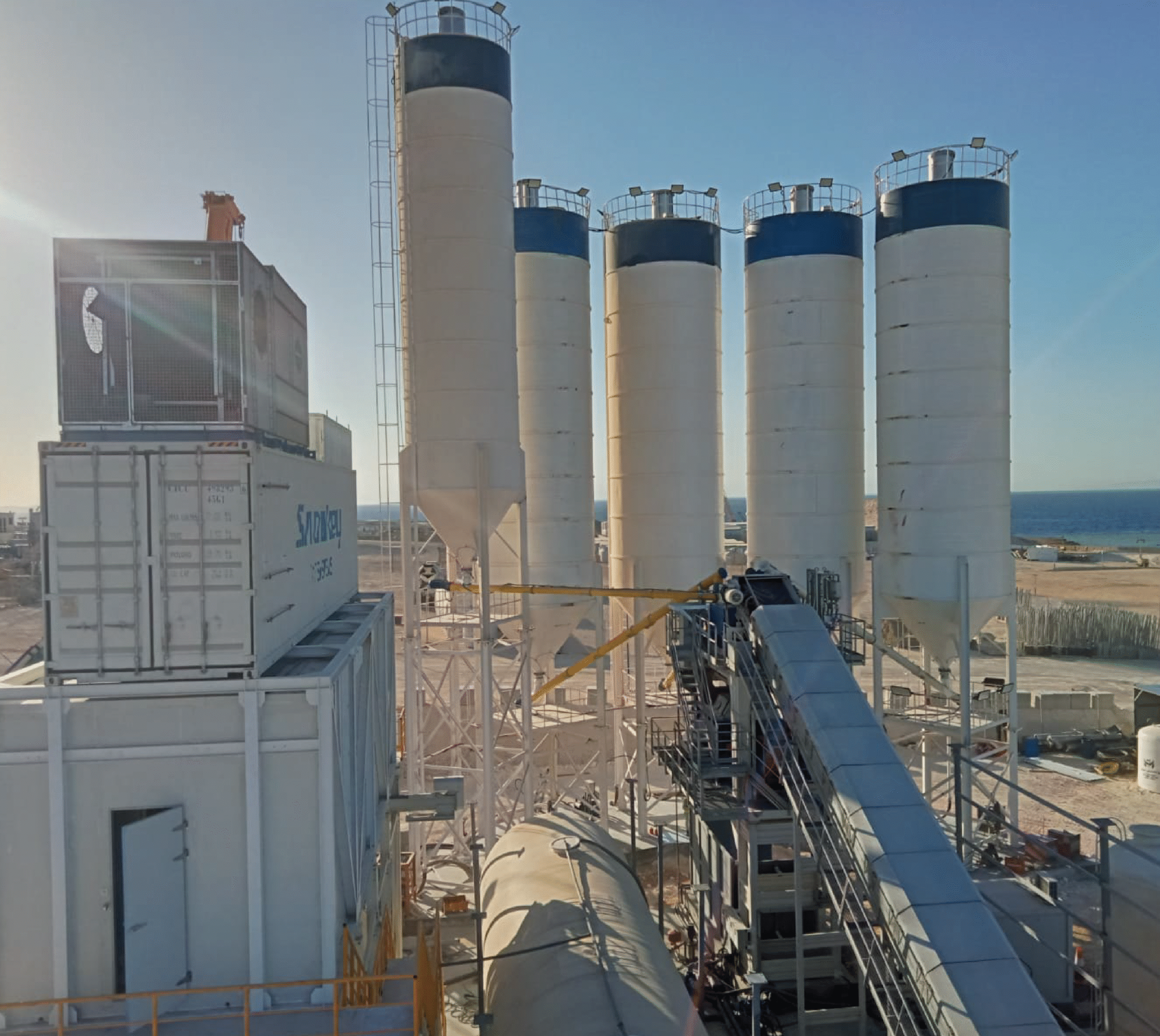

At ASAS Al-Mohileb, we proudly operate one of the largest, most advanced, and environmentally responsible concrete production complexes in the world, located at the heart of The Line. More than just a plant, this facility is a living symbol of innovation, efficiency, and environmental responsibility.

Developed as a strategic partnership with NEOM, and built entirely through a SAR 700 million private investment from ASAS

Al-Mohileb, the complex delivers over 20,000 cubic meters of green concrete daily, contributing to the realization of NEOM’s ambitious vision and the Kingdom’s aspirations for a sustainable future — with precision, reliability, and advanced environmental awareness.

The complex includes 10 high-capacity batching plants, producing up to 2,000 cubic meters per hour, enabling continuous large-scale supply. To meet the challenges of harsh desert climates, the facility is supported by an integrated cooling system comprising:

To ensure the highest levels of accuracy and consistency, the facility features a state-of-the-art concrete testing laboratory, equipped with the latest technologies and instruments for quality control and mix optimization. Every concrete truck is subjected to precise testing in accordance with NEOM’s unique specifications, ensuring strength, durability, and thermal performance under even the most challenging climate conditions.

Our commitment is rooted in environmental responsibility. We rely on green cement, the result of a collaboration with Al-Jouf Cement Factory and our in-house engineering expertise, offering both high quality and low carbon emissions. The complex is also equipped with two CarbonCure units, which inject captured CO₂ into the fresh concrete mix. The carbon instantly mineralizes within the mix, permanently embedded, reducing cement consumption while maintaining structural integrity.

In addition, the complex hosts two advanced concrete recycling systems, with a capacity of 60 cubic meters per hour, significantly reducing waste and supporting the vision of sustainable construction. A dedicated water treatment plant with a capacity of 600 cubic meters per day treats all types of water used within the complex, including industrial and sanitary wastewater, achieving near-total water efficiency and minimizing environmental impact.

The complex is supported by an integrated logistics network and large-scale storage for all essential raw materials—including cement, aggregates, sand, and water—ensuring continuous production, full operational readiness, and rapid response to any technical emergency.

The facility is designed for full operational autonomy, with dedicated on-site maintenance teams and readily available spare parts—ensuring uninterrupted production. This is more than a concrete facility; it is a living embodiment of high environmental values and a global benchmark in the ready-mix industry.

In a strategic move that reflects its growing expertise and advanced operational capabilities, ASAS Al-Mohileb has successfully established a fully integrated stationary concrete batching plant on Shusha Island, a remote location known for its logistical and climatic challenges. During the construction and setup phase, the company transported all required equipment and heavy machinery using its own barge, completing the installation within the scheduled timeframe without relying on external logistical support.

This achievement highlights ASAS Al-Mohileb’s self-sufficiency and ability to execute complex operations in isolated environments. In the operational phase, the company ensured the steady and timely supply of raw materials – including aggregate, cement, and water – in full alignment with the production schedule, thereby avoiding any disruption to concrete supply for contractors. This was achieved despite the inherent difficulties of accessing the island and the unpredictable weather conditions. The project stands as a compelling example of integrated planning, logistical independence, and execution under challenging conditions, further reinforcing ASAS Al-Mohileb’s reputation as a trusted partner in specialized infrastructure development across demanding and remote locations.

Asas Almohileb 2025. Powered by Bepro