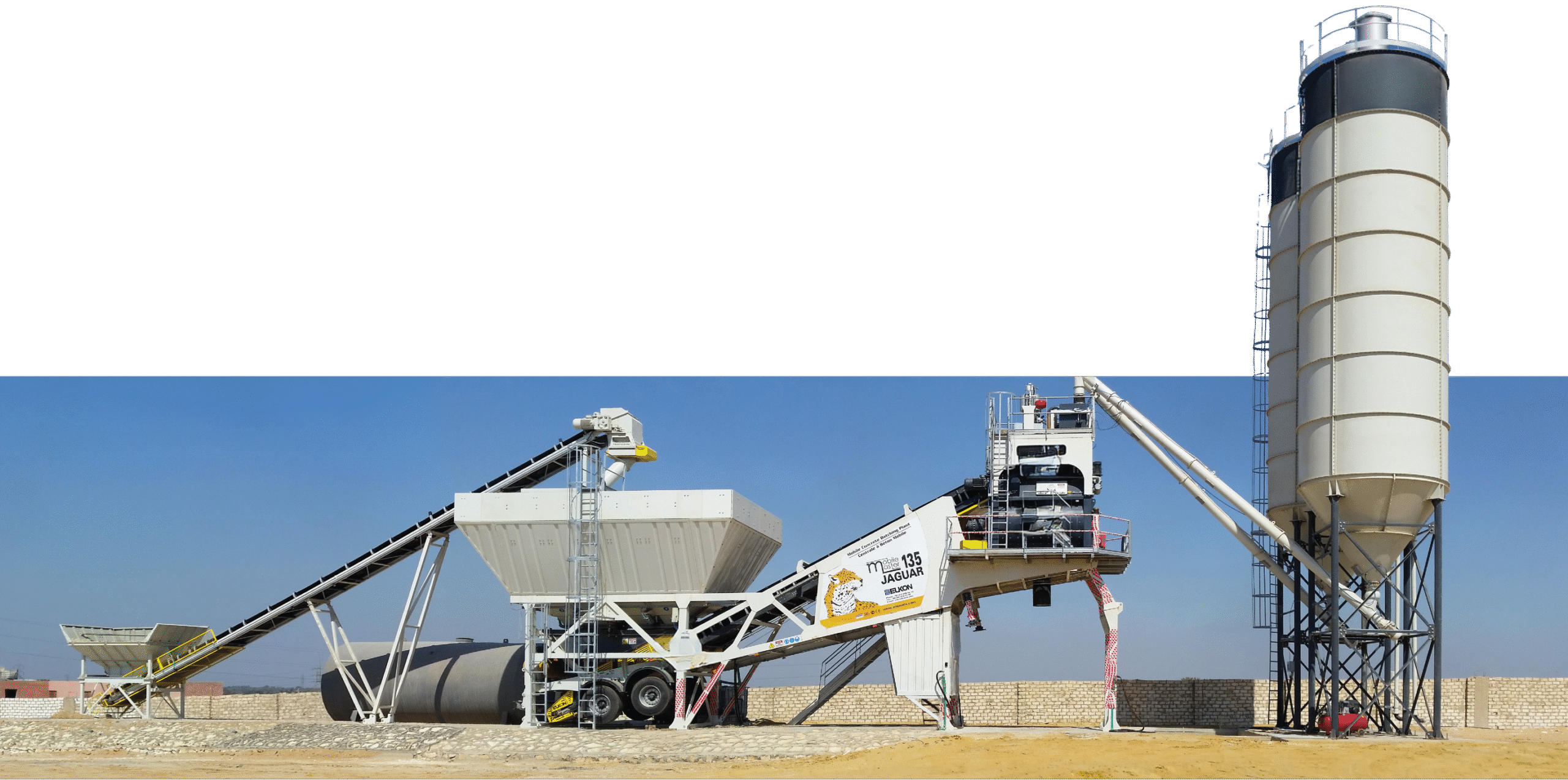

At ASAS AlMohileb, we rely on an advanced system of stationary and mobile concrete plants, designed to meet diverse project needs with outstanding efficiency and quality. These plants comply with the highest technical specifications and consulting standards, offering flexible performance that adapts to site conditions and fast-paced execution schedules.

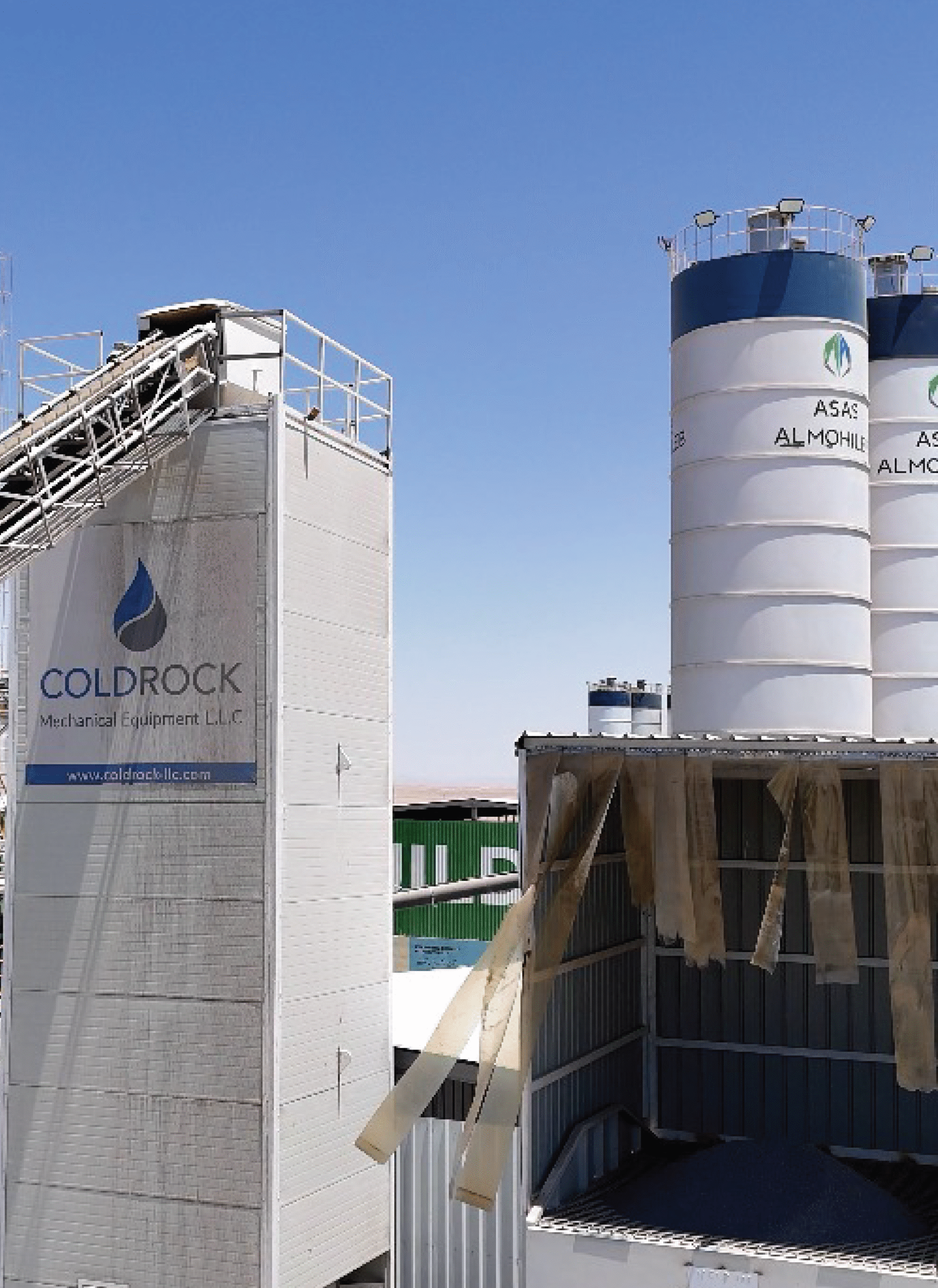

Our stationary concrete plants are built for high production capacity without compromising on quality. Drawing from our accumulated field expertise, we have equipped these plants with all necessary systems and components to produce a wide variety of concrete mixes that meet the complex requirements of large-scale projects and their consultants with precision and reliability.

As for our mobile concrete plants, they provide a smart solution for projects requiring rapid deployment or operating in limited-space environments. With easy transport and quick installation, they are ideal for residential areas, roadworks, and space-constrained sites. Their modular design enables efficient on-site concrete production, reducing delays and lowering operational costs.

Thanks to this operational diversity, our concrete plants empower us to deliver precise, efficient, and integrated concrete solutions that meet the expectations of engineers and consultants alike—tailored to the unique scale and demands of every project.

At ASAS AlMohileb, we operate a fully integrated fleet of equipment specialized in transporting and placing ready-mix concrete. This fleet serves as a cornerstone of execution quality and operational efficiency, granting us the flexibility to manage projects of varying scales and complexities.

Transit mixers are responsible for delivering concrete from our batching plants to project sites, while preserving its core properties and operational performance. These mixers form the critical link between precision in production and excellence in placement—ensuring that concrete arrives in optimal condition, ready for pouring without any compromise in specifications.

To meet the diverse demands of concrete placement across various job sites, we offer two types of concrete pumps: First, mobile pumps with boom lengths up to 63 meters, enabling precise coverage in space-restricted areas or horizontally expansive pours.

Second, stationary concrete pumps, which are used specifically for high-rise buildings, seamlessly integrated with vertical placing booms to deliver concrete efficiently and accurately to elevated floors without disruption.

To ensure smooth operations and precise timing, the company employs an advanced fleet management system, supported by a robust logistical network. This enables on-time concrete delivery to project locations and ensures the uninterrupted supply of raw materials to our production facilities—reinforcing our commitment to quality, precision, and operational continuity.

In the fast-paced world of ready-mix concrete production, the seamless delivery of raw materials is a cornerstone of operational efficiency. Our expansive fleet of cement bulkers, tippers, and transport trailers forms the backbone of this system—ensuring that materials reach our plants swiftly and reliably.

This integrated fleet guarantees consistent availability of materials, preventing delays in supply and keeping projects on schedule. Through efficient logistics coordination, we reduce wait times and enhance overall productivity across sites.

This entire operation is supported by a sophisticated logistics system that combines intelligent planning with agile response. Our advanced tracking technology directs vehicles along the shortest and most prioritized routes, helping save time and fuel. We also place strong emphasis on road safety standards, operating a modern fleet with reduced carbon emissions—supporting environmental sustainability and responsible resource management. Each delivery is not only efficient, but guided by a deep commitment to people and planet alike The fleet’s scale and coverage provide us with high flexibility to serve projects of all sizes and to adapt swiftly to client needs. It also enables us to service multiple locations simultaneously, including remote areas, without compromising performance or execution quality.

Regular and preventive maintenance is a cornerstone of seamless project execution. With a comprehensive inventory of spare parts and mobile workshops, we minimize downtime and ensure uninterrupted operations across all working environments.

Our specialized maintenance team implements scheduled programs that cover all stationary and mobile equipment, ensuring stable performance, extended operational lifespan, and

Preventive servicing also enhances fuel efficiency and reduces emissions—positively contributing to environmental responsibility. Well maintained equipment runs smoothly, consumes less fuel, and produces lower levels of pollution, making construction operations more sustainable and eco conscious.

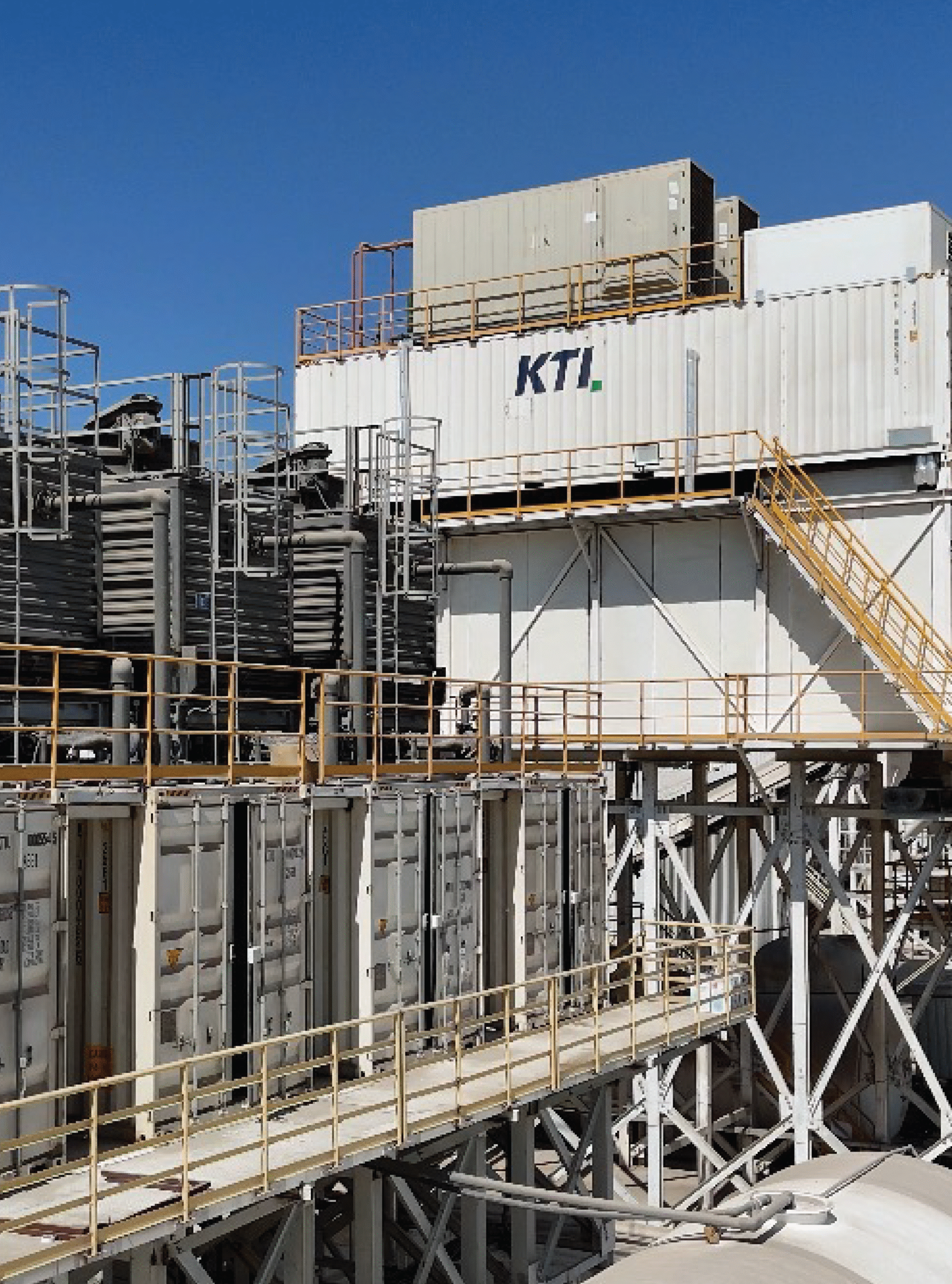

Controlling concrete temperature is essential to ensuring its strength, durability, and long-term performance—particularly in the high-heat climate of Saudi Arabia. Elevated ambient temperatures can accelerate the setting process, compromising concrete quality and structural integrity. To address this challenge, we have invested in an integrated system that includes high-efficiency water chillers, advanced high-capacity ice plants, and aggregate cooling systems. These solutions—used individually or in combination—help lower mix temperatures and ensure full compliance with the most stringent project specifications.

For projects that require very low concrete temperatures, reaching as low as 22°C during peak summer conditions, ice alone may be insufficient or inefficient, and may also impact production capacity. In such cases, aggregate cooling provides a pioneering technical solution—one of the first of its kind in the Kingdom—offering superior efficiency, faster performance, cost-effective operation, and enhanced environmental sustainability.

By pre-cooling aggregates before mixing, we are able to achieve the desired concrete temperatures without compromising production capacity, enabling us to meet strict thermal requirements while maintaining a steady and efficient production rhythm, even under the most demanding climate conditions.

Asas Almohileb 2025. Powered by Bepro